Searching for leaks and defects

Purpose of analysis

The purpose of these calculations is to identify various hydraulic anomalies (leaks, unauthorized offtake, valve malfunctions, diameter narrowings) in a heat network by using a hydraulic model and meter readings simultaneously.

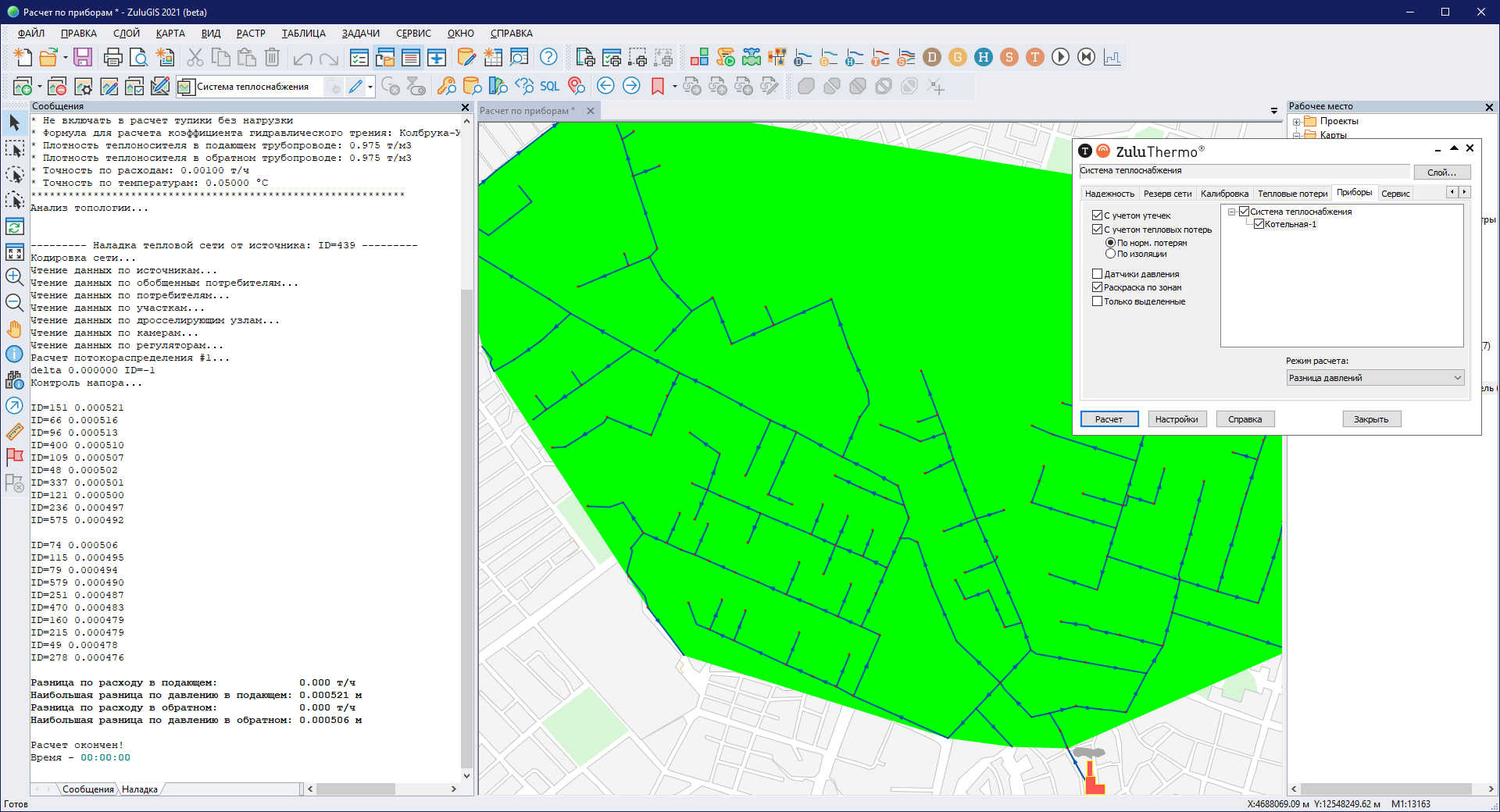

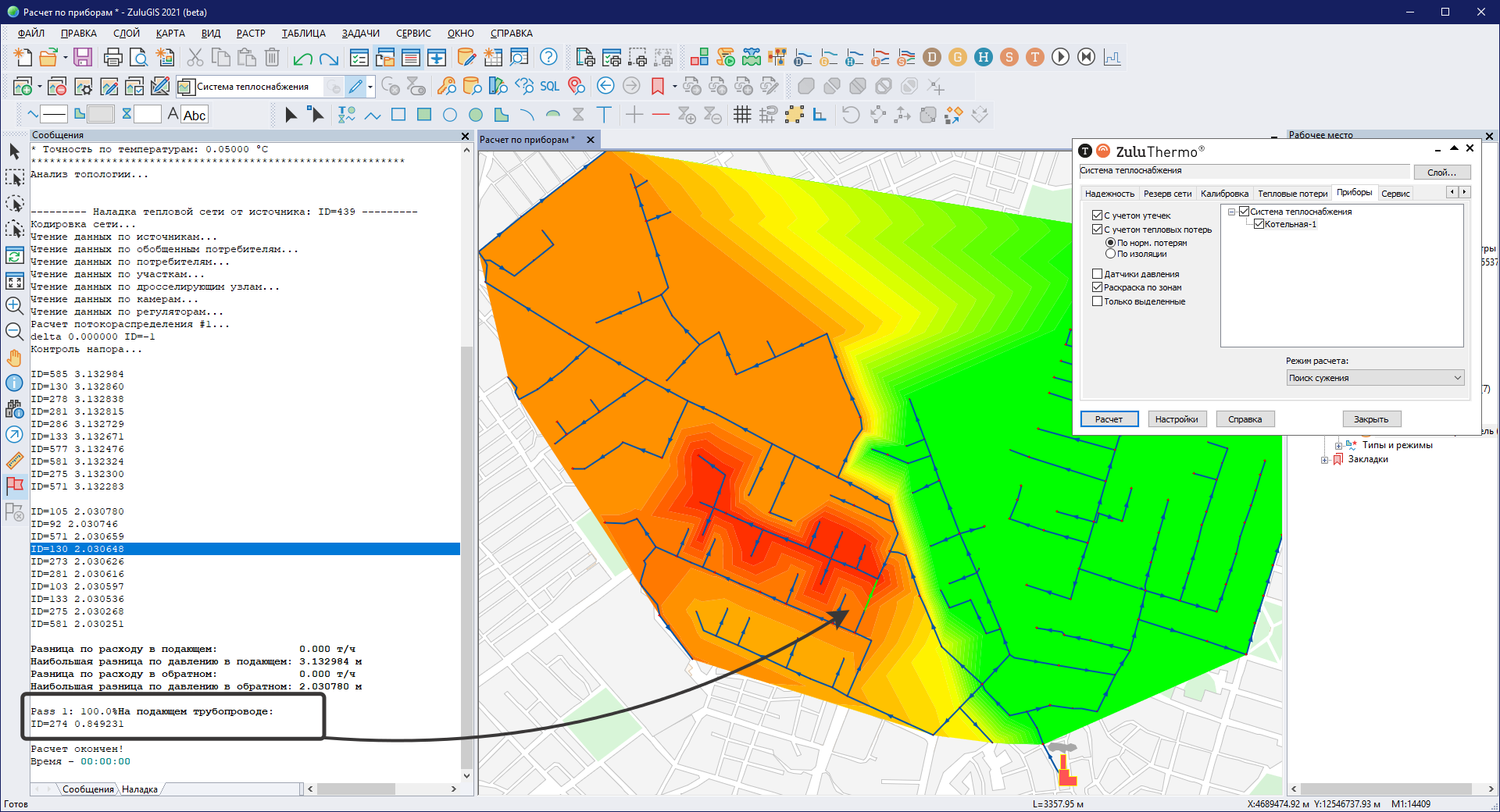

Detecting and visualizing divergencies between a hydraulic simulation model and instrument readings

If the hydraulic model of the heat network has been calibrated, the hydraulic analysis performed for current consumer demands should result in pressure values at nodes matching the readings of pressure meters.

It is possible to take meter readings and perform the corresponding hydraulic analysis at set intervals.

If during the measurement period there have been changes in the actual system that are not described in the hydraulic model (leakage, unauthorized withdrawal from the network, change in pipe friction caused by a malfunctioning valve, and so on), the hydraulic analysis will detect the discrepancy between the design pressures and the pressure gauge readings as well as the difference between the total flow rate at the reservoirs in the model and the flowmeter readings.

It is possible to detect and visualize divergencies between a hydraulic simulation model and meter readings in real time. To do this, you need to specify the time of automatic recalculation of the model in the calculation settings. As a result of automatic calculation, updated data will be recorded in the fields for calculation results; if temporal color-codings and labels are included, they will also be updated.

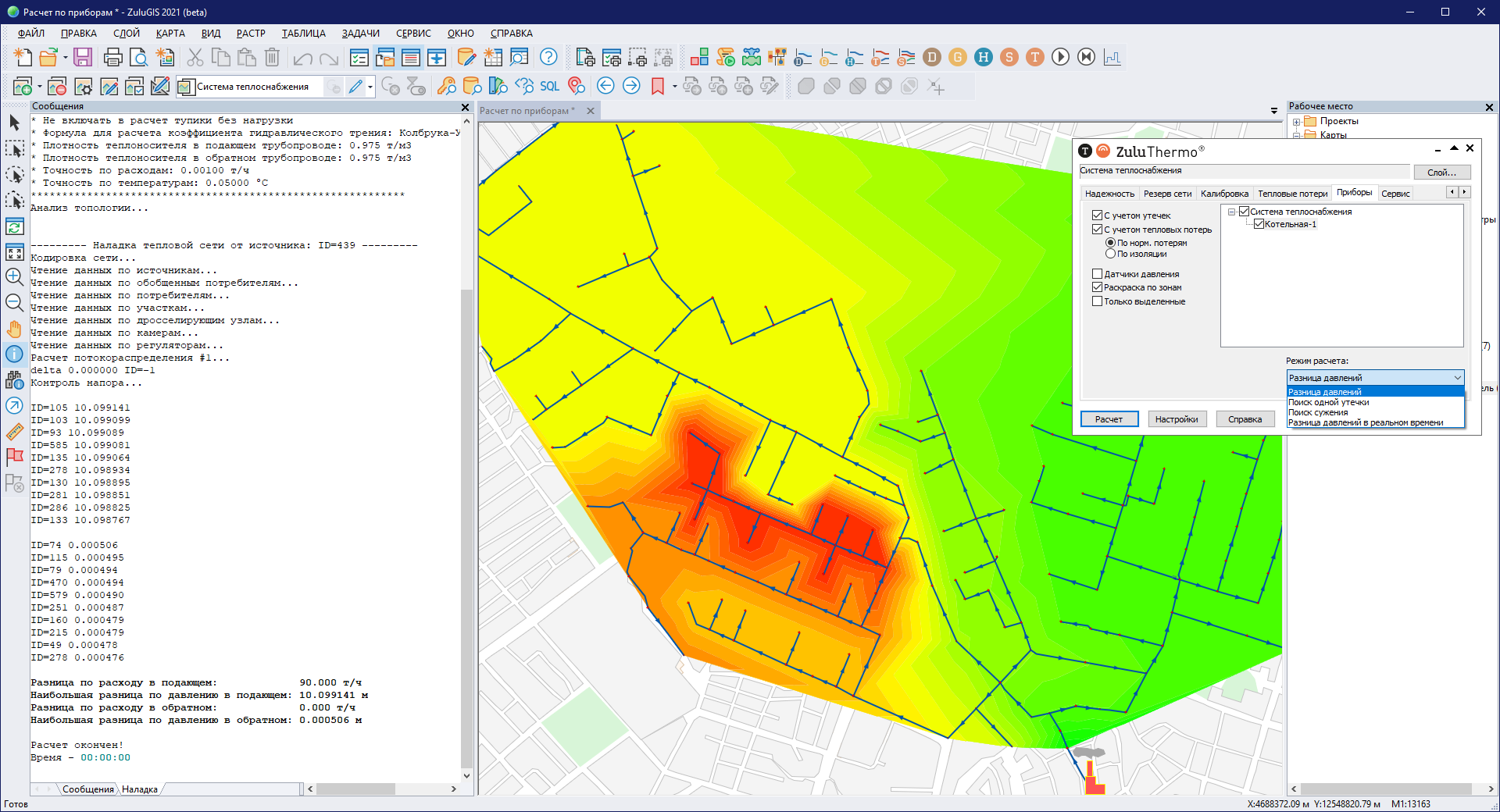

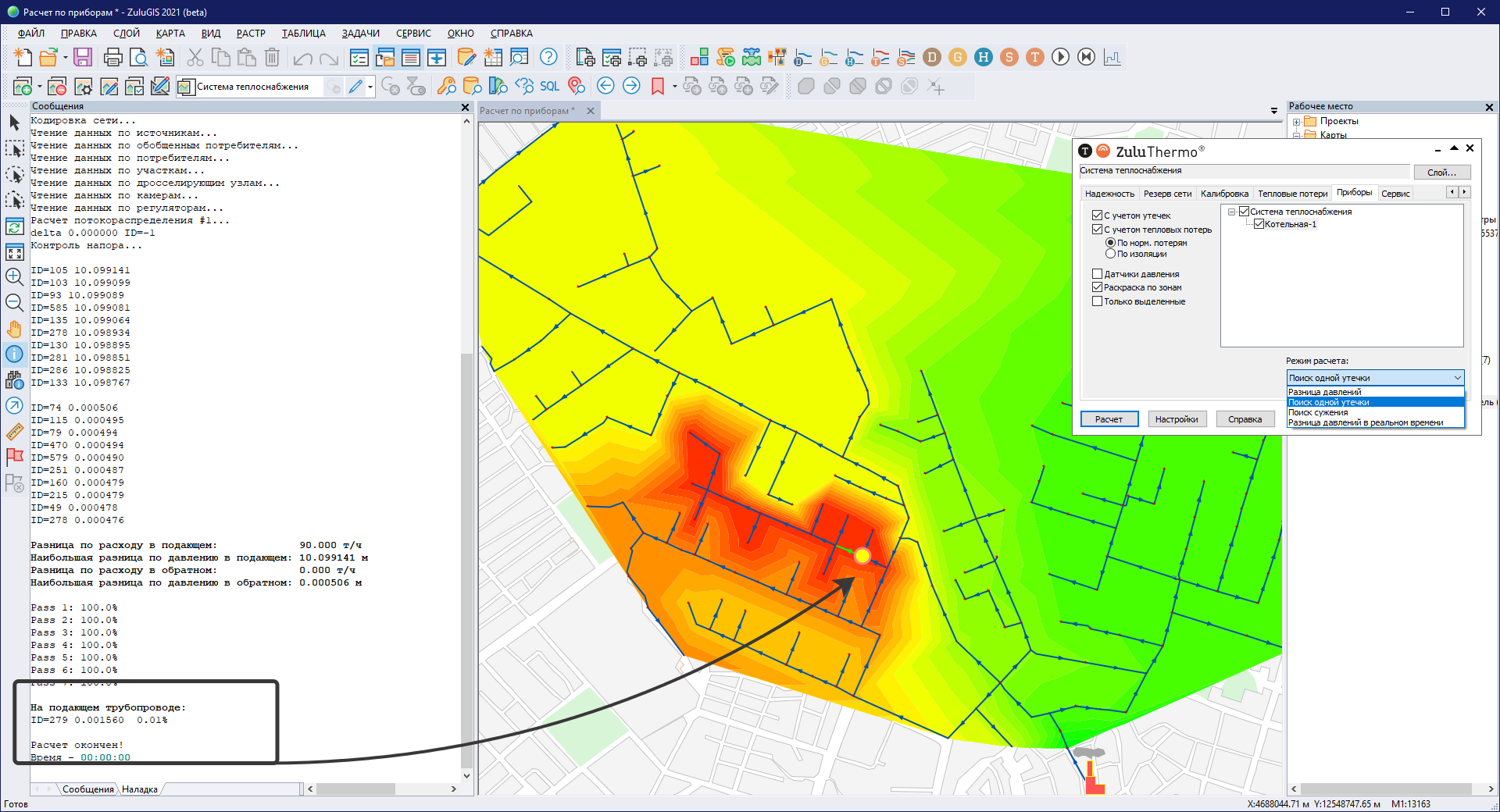

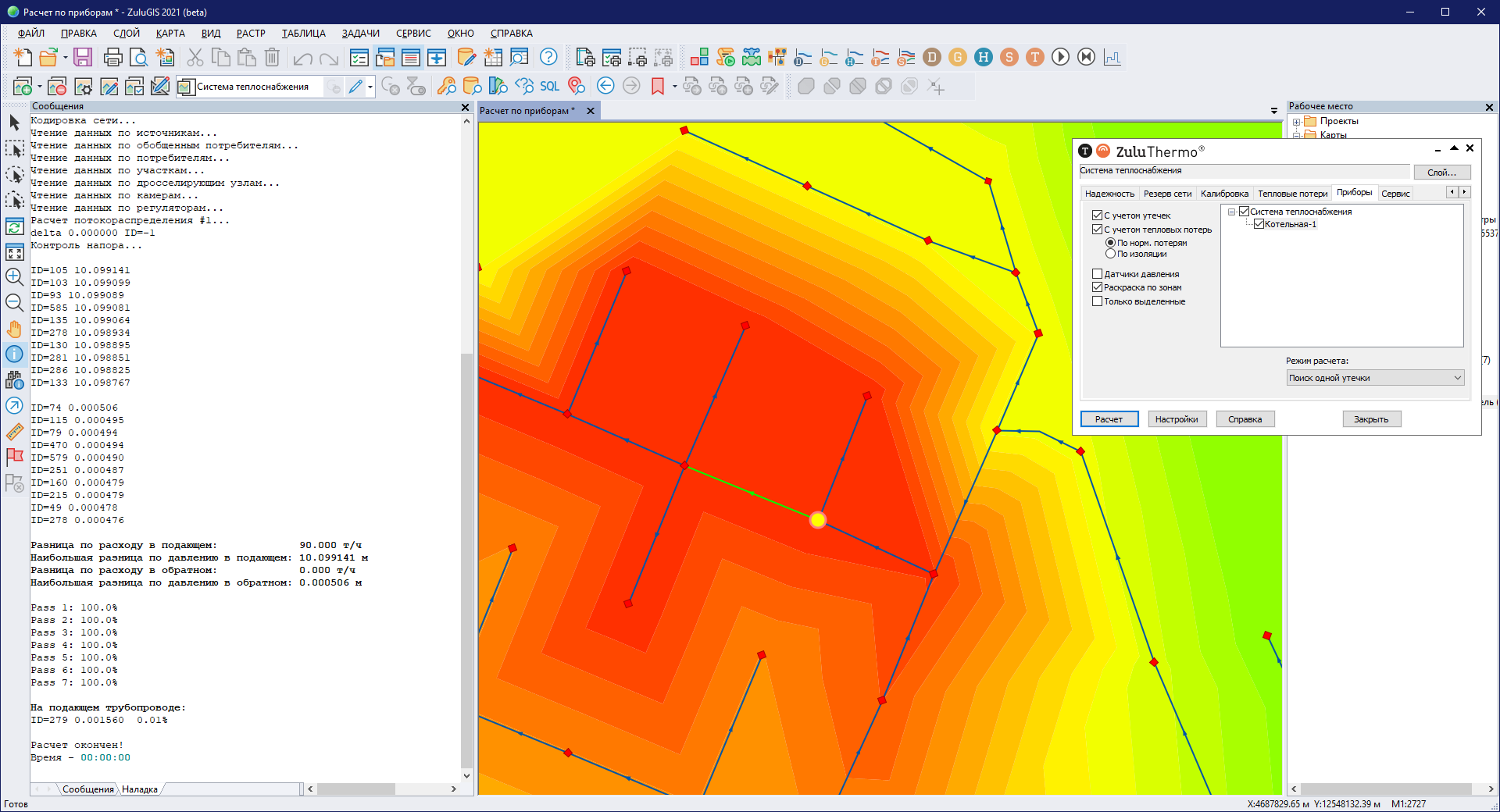

Locating a leak

If the flow rate at the reservoir according to the flowmeter has become noticeably higher than the flow rate in the hydraulic model, it can be assumed that there is a leak.

Ideally, it is possible to trace a spot leak up to its exact location in a particular section of the network.

The actual tracing accuracy depends on the quality of the hydraulic model, the number, accuracy, and location of network meters, and taking simultaneous readings.

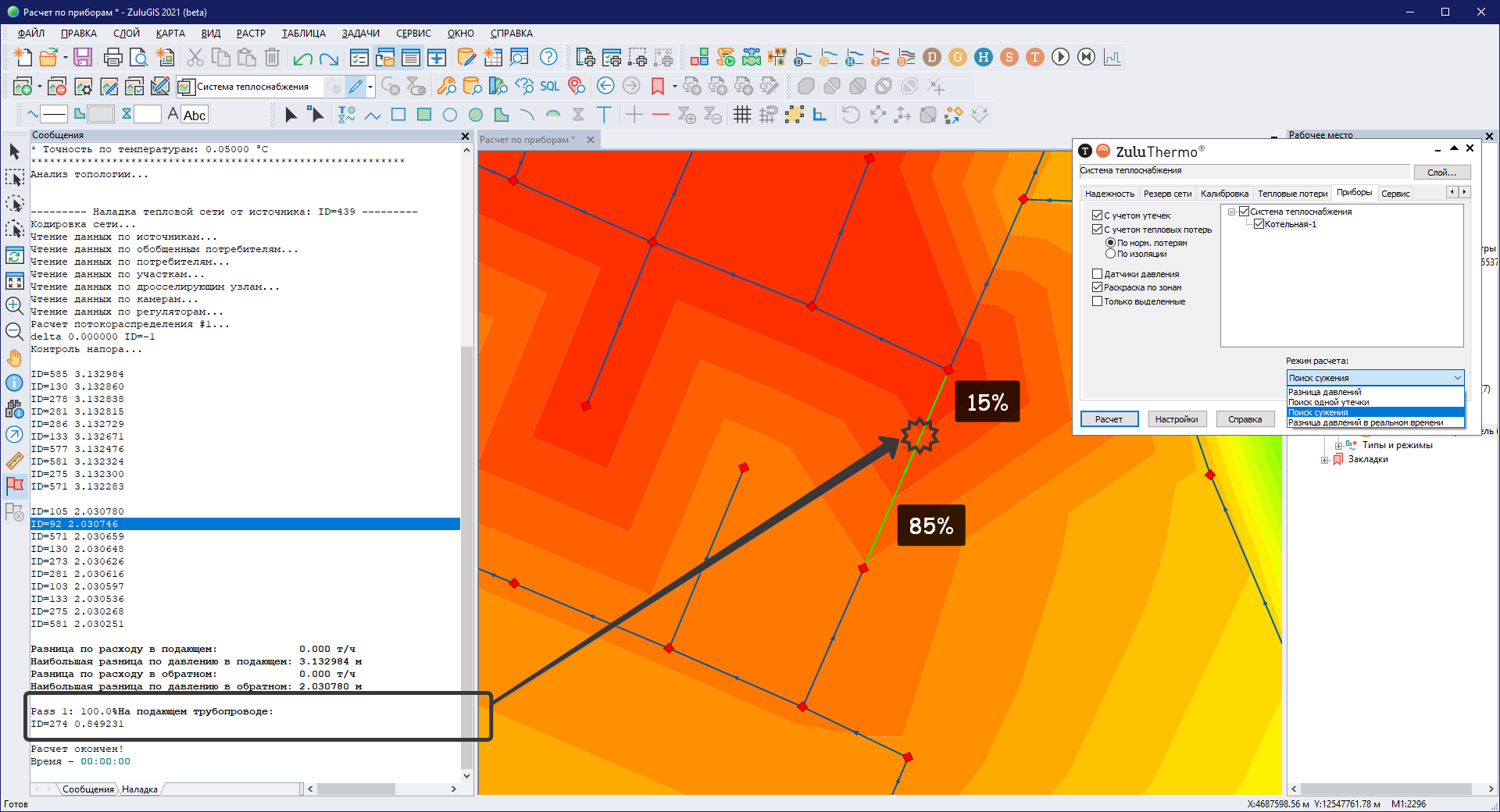

Locating a pipe narrowing

If the flow rate at the reservoir according to the flowmeter corresponds to the flow rate in the hydraulic model but there are noticeable differences in pressure at the system nodes, it can be assumed that a change in frictional loss occurs in the system pipe.

It is possible to locate the defect that occurred in the system pipe and was caused by the change in friction right down to the pipe.

These calculations require a license for simulation modeling!

See also: Heat network calibration